Vehicle brake development

Simple, accurate and repeatable brake testing.

What are the challenges facing modern brake system development?

A well designed brake system inspires driver confidence through the pedal feel and is ultimately a key part of a vehicle's DNA. Modern vehicle brake development presents a variety of challenges including safety, reliability, electrification, integration with ADAS, noise reduction, vibration control, and environmental impact. We help our automotive customers enhance their braking system performance by providing market-leading testing solutions that include brake robots, ADAS targets and platforms, and synchronising software.

Our brake development solution

Ensuring brake systems are reliable and safe remains a top priority within the automotive sector. Our robots empower engineers to optimise their brake systems by providing track test technologies that allow precise testing and provide data-driven insights that ultimately ensure safer and more efficient vehicles.

Precise speed control

The Combined Brake and Accelerator Robot (CBAR) provides repeatable and accurate speed control, which coupled with a steering robot, allows for complex control of the vehicle. This is essential for ADAS testing and for path following applications such as driverless durability testing.

CBAR 600

Collision avoidance ADAS development

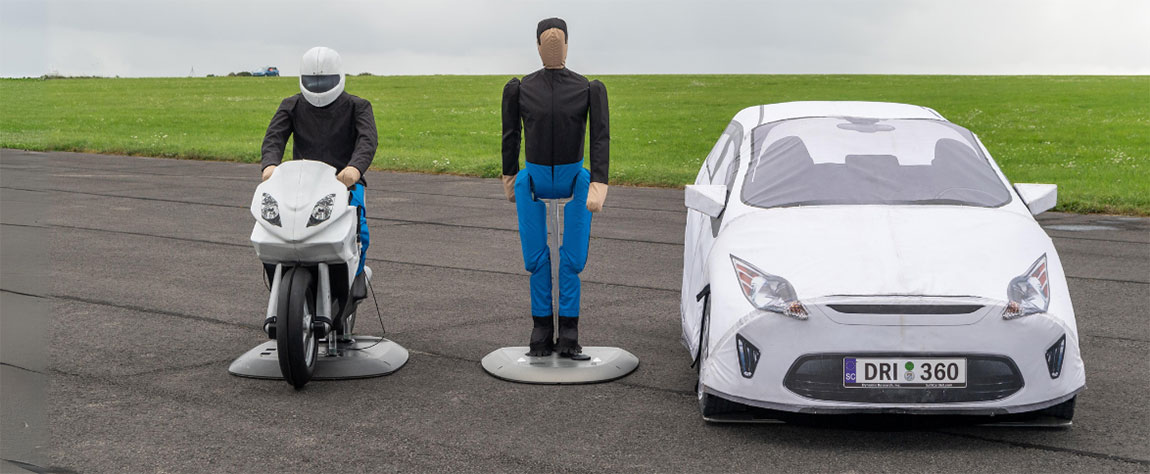

Modern brake systems must seamlessly integrate with ADAS features such emergency braking. Our soft ADAS targets and accurate ADAS platforms allow no-harm testing of auto-braking systems (AEB, CIB, DBS). Synchro technology is used to regulate car-to-target position and speed, ensuring that test object intersections take place exactly as planned.

Track testing

Objective brake feel analysis

With the introduction of electrification and regenerative braking, brake development is undergoing an evolutionary change. Regenerative systems require the blending of braking torque from the regenerative and the foundation braking systems, which makes achieving optimal brake feeling challenging. Yet the customer expects the same levels of control, confidence, and performance as before.

Our brake robots provide a repeatable and accurate method of applying the brake, allowing you to understand the relative influence of each system on brake feel. Pedal input scenarios are programmed using RC Software, with graphing and data export tools enabling influence of the regenerative and foundation systems to be accurately determined.

With accurate, objective data at your fingertips you can easily identify opportunities for brake controller tuning and achieve the levels of brake feeling and performance that customers expect.

Driving robots

Vehicle homologation

Vehicle homologation is a critical process that ensures a vehicle complies with safety, environmental, and technical regulations before it can be legally sold or operated on public roads. It involves rigorous testing and certification to verify that the vehicle meets the specified standards.

Our brake robots provide repeatable, fast, high load inputs, making it ideal for homologation tests such as ECE 139 – Brake Assist Systems (BAS) or ECE 13 Secondary Performance.

Brake Robot

Need to discuss your brake development requirements?

"*" indicates required fields