Cyclist safety remains a worldwide concern, with alarming statistics highlighting their vulnerability on the roads. With this in mind, we sat down with Nathaniel (Nate) Kuhl, Product Development Engineer at Dynamic Research, Inc. (DRI), to get a behind-the-scenes look at the design and development of the new Soft Bicycle 360™ ADAS target. From addressing critical safety challenges to innovative engineering solutions, Nate shares his insights into how this next-generation target was created.

Let’s start with a basic question, why a cyclist target?

The sobering reality is that cyclist safety remains a critical concern worldwide. When we look at the data, we're seeing that cyclists are the only road user group in the EU where fatalities haven't decreased since 2010. In the US, cyclist fatalities have actually increased by 22% between 2007 and 2018, while overall traffic fatalities decreased.

As a keen cyclist myself, I am glad to say that the industry is looking to address this, and a greater focus is being placed on protecting this vulnerable road user group. For example, organisations like Euro NCAP are expanding their testing protocols to include more cyclist scenarios.

But why develop the Soft Bicycle 360 when there are other ADAS bicycle targets already available on the market?

Good question. As the number of cyclist test scenarios grows and becomes more sophisticated, the industry needs a target that can keep up with these demands while addressing the practical challenges our customers face every day. The big issue we’ve seen with previous targets is that they can cause damage to vehicles under test. Even minor damage – something as simple as knocking a sensor out of alignment – can cause major delays in test programmes. So, we knew we needed to completely rethink the approach to bicycle target design to solve this.

What were the main design goals when developing the Soft Bicycle 360?

We actually had four key pillars driving our design: performance, realism, damage minimisation, and durability. It's quite a balancing act because these requirements sometimes conflict with each other. For instance, we needed the target to be soft enough to prevent damage to test vehicles, but also rigid enough to maintain stability at speeds up to 40 km/h. We ended up with a product 30% lighter than existing alternatives that can still withstand impacts at up to 60 km/h.

Can you tell me about the features that set the Soft Bicycle 360 apart from other bicycle targets?

Certainly! One of the key differences is the single piece rubberised hollow frame. This eliminates the traditional connectors, which are typically the first point of failure in other targets. We have strategically reinforced it where necessary, kind of like giving the frame an endoskeleton that provides strength exactly where it's needed.

I am particularly proud of the wheel design. It uses a durable plastic core wrapped in foam and instead of metal spokes, we use soft nylon strings. This is an idea inspired by watching mountain bike racing on weekends. It reduces weight, which is great for a racing bike, whilst still maintaining strength. In our case, the benefit is minimising damage to test vehicles.

Plus, the target can travel in reverse, which might sound simple but it's a huge time-saver for test engineers who previously had to manually reposition targets between tests with other targets.

What challenges did you face during the design process, and how did you overcome them?

The biggest challenge was what we called the "Goldilocks problem", trying to balance the various design targets for the best all-round product. Too soft, and the target becomes unstable at higher speeds. Too rigid, and we risk damaging test vehicles. We had to get it just right. At the same time, we had to ensure the target can withstand a lifetime of being hit by cars repeatably. It is quite the challenge!

So how did you ensure it remains durable?

We took a holistic approach to durability and used a mix of material science and engineering. For example, the modular rider is made from lightweight hollow materials but wrapped in abrasion-resistant clothing. The other key feature is our separable design. In low-speed collisions, the target stays intact to maximise testing efficiency. But at higher speeds, where damage risk increases, it separates into smaller components to reduce impact forces.

How did you make the Soft Bicycle 360 realistic?

Well, there are two answers to this. We must make it realistic visually for humans and cameras. But we also must make it ‘look’ like a cyclist to other vehicle perception sensors, such as radar and LiDAR.

Visually, we ensured compliance with ISO-19206-4, which essentially matches the rider’s dimensions to a 50th percentile male adult rider. For the bike itself, we incorporated actual bicycle components like front fenders, grips, spokes and wheel reflectors.

But, as I say, it is also critical that vehicle sensors ‘see’ the target as a real bicycle. DRI actually has developed our own radar measurement device, so we spent many an hour on the test track fine-tuning the target’s radar cross-section to ensure it was representative and conformed to the necessary standards.

What kind of testing did the Soft Bicycle 360 undergo before its release?

We conduct a lot of ADAS testing at our California proving ground for customers, so we have a good feel for what is required from a target like this. Having used previous cycle targets we knew how they could be improved and what we wanted to achieve. Feedback from our test engineers and others in the industry highlighted the need for reduced downtime and easier resets. That’s why the Soft Bicycle 360 can travel in reverse and has fewer parts, making it quicker to rebuild after an impact.

The Soft Bicycle 360 was subjected to extensive collision testing at speeds up to 60 km/h. We also conducted abrasion tests and validation against various sensor systems to ensure it performed as intended under real-world conditions. We have really put it through its paces, just like our customers are going to!

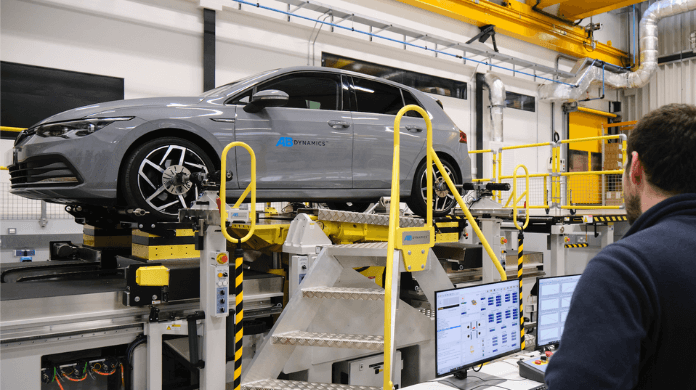

How does the Soft Bicycle 360 integrate with existing ADAS testing systems?

That’s a good question because the target itself is only half of the solution. Making the Soft Bicycle 360 compatible with the entire range LaunchPad and SPT platforms was a key consideration from day one. This means our customers can easily incorporate it into their existing test setups, they can just swap out the bicycle target for the motorcycle or pedestrian targets, for example.

What industry test protocols is the Soft Bicycle 360 designed for?

The Soft Bicycle 360 has been designed to meet the requirements of all major global ADAS testing protocols that necessitate a bicycle target. This applies to test procedures from NHTSA in North America, Euro NCAP in Europe, and UNECE regulations globally. For example, this includes Euro NCAPs new Truck Safe cyclist tests (HBNA-50, HBLA-25/50 and HBNtap).

You are at the centre of vehicle testing and safety, any final thoughts on the future of ADAS systems and safety in the industry?

Personally, it really is quite exciting to be involved with the development of the Soft Bicycle 360. When I drive down the highway in five years, I will likely be surrounded by cars that encountered the target during their development programmes. It is rewarding to know that DRI and I have played a part in developing better ADAS systems and, ultimately, that means safer roads for everyone.

More widely, safety standards are becoming more stringent, which is great to see. The result of this will be increasingly more sophisticated ADAS systems, which will in turn need increasingly more sophisticated test scenarios to make sure they perform properly. We designed the Soft Bicycle 360 with this in mind. Not only does it meet today's testing needs, but we have an eye toward future requirements too.

Key takeaways:

- Critical need for cyclist safety: Cyclist fatalities have not decreased in the EU since 2010, and in the US, they increased by 22% between 2007 and 2018, highlighting the critical need for improved road safety.

- Innovative engineering for ADAS testing: The Soft Bicycle 360 was created with four key design criteria; performance, realism, damage minimisation, and durability. The result is a target that is 30% lighter than existing alternatives and can withstand impacts up to 60 km/h.

- Unique design features: A single-piece frame architecture, soft nylon spoke wheels, and modular rider design enhance realism, reduce vehicle damage, and ensure durability during repeated impacts.

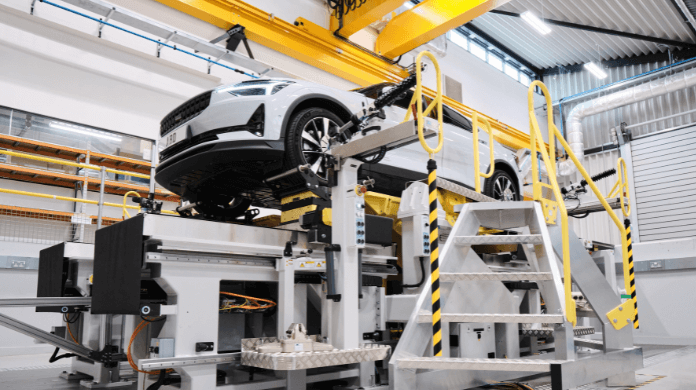

- Extensive testing and compatibility: The target underwent rigorous testing, including sensor validation and durability testing. It integrates seamlessly with AB Dynamics range of VRU target motion platforms and is compatible with NCAP, NHTSA, and UNECE tests.

- Future-focused development: Designed to address current and anticipated ADAS testing requirements, the Soft Bicycle 360 reflects the industry's growing emphasis on vulnerable road user protection and more complex testing scenarios.

For more information on the Soft Bicycle 360 see the product page here or contact us to see how AB Dynamics can support your ADAS testing programme.