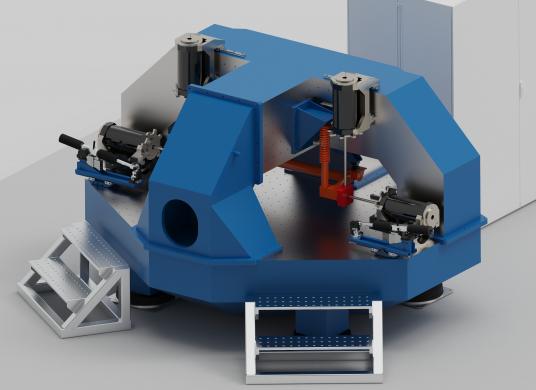

New Axle level NVH test rig highlights NVH issues earlier in the design process; reducing costs and time to market

- Use of novel linear electric actuator provides market-leading operating frequency range, outperforming traditional hydraulic alternatives

- Suitable for passenger, light commercial and electric vehicle testing

AB Dynamics has launched a new axle level NVH rig, the ANVH 250, following demand from vehicle manufacturers to ascertain NVH issues earlier in the design process and over a greater operating range. Electrified powertrains have significantly lowered the acceptable level of NVH for vehicle manufacturers.

“The ANVH 250 enables manufacturers to measure and optimise the NVH characteristics of suspension systems during the vehicle design process, helping to produce a cost-effective suspension design that delivers high levels of cabin refinement,” explained Edward Haynes, Chief Engineer – Electric Actuators “The ability to assess the suspension's NVH characteristics at an early stage over a large frequency range avoids expensive revisions at later stages of a vehicle program to rectify NVH concerns, helping reduce product time-to-market.”

The ANVH 250 measures NVH transmission from wheel hubs, through suspension components, to the suspension mounting points. It accurately measures the transmission of forces up to 250Hz through the suspension springs, dampers, linkages, anti-roll bars, and elastomeric bushes. The class-leading performance is achieved by using an innovative and exceptionally stiff design of frame in combination with AB Dynamics' unique high frequency linear actuators, specifically designed for this application. The direct-acting electric linear actuators delivers motion over a frequency, displacement and load range not achievable with any available hydraulic actuator, whilst being inherently safer, cleaner, quieter and more efficient than their hydraulic counterparts.

With the ongoing transition to electric vehicles with low background noise levels, it has become increasingly important to control or eliminate NVH sources from the vehicle suspension and driveline. With the ANVH 250, AB Dynamics has produced an accurate, cost effective, easy to use and reliable test machine that allows fine-tuning of the suspension's NVH characteristics to be done at a much earlier stage in the design process. The ANVH 250 builds on AB Dynamics’ vast experience in producing laboratory test equipment for the international automotive market with proven products such as the SPMM and aVDS which rely on accurate motion control and precise measurement. With an axle installed, the actuators apply precise motion to each hub at frequencies from 0-250Hz and displacements from +/-0.01 to +/-50mm while tri-axial load cells measure the forces transmitted to each vehicle attachment point. The ANVH 250 can apply sinusoidal, random input and road load data displacements to the axle system. Displacements can be applied to the wheel hubs in the vertical (Z), longitudinal (X) or lateral (Y) directions. The paired displacements at the hubs can be in phase or in anti-phase.

A graphical user interface allows the operator to easily navigate between different parts of the system to control the machine and configure the test procedure. All data relating to the axles tested and the tests performed, as well as system configuration and instrumentation settings, are stored in an easy to use and search relational database system. Key axle data is entered via the interface screen. As with all data entry screens in the system, data items are checked as they are entered to prevent the user from entering data that does not comply with any limits associated with the data field. The ANVH 250 is supplied with ANVH Grapher. This is a screen-plotting program that enables results to be viewed as soon as a test is completed so that the user can check the test has run successfully and produced meaningful data.

The rig is suitable for axles with a track width of between 1450-1750mm and an apparent mass at the wheel hub of up to 45kg, making it compatible for testing the majority of passenger and light commercial vehicles. As an option, the aNVH rig can be supplied with the Dynamic Arm Wheel Position Measurement System (WPMS) for high accuracy measurement of the wheel hub motion in all six degrees of freedom. The Dynamic Arm WPMS was specifically developed for use on AB Dynamics’ SPMM 5000E Kinematics and Compliance test machine. It's use on the ANVH provides the user with valuable axle-level K&C data.

“Our new ANVH 250 rig is the perfect complement to our existing test products, ensuring that AB Dynamics continues to offer customers a complete range of leading-edge testing technologies to accelerate the development of next-generation vehicles. Our portfolio covers the entire development process including simulation, lab-based testing and track testing,” concludes Edward Haynes.

Click here to find out more about the ANVH 250 or get in touch with us today to discuss this further.